Bronpi Heating, Lucena, Spain

100% tightness for comfortable warmth

Bronpi Calefacción, based in Lucena, southern Spain, develops and manufactures high-quality fire places, wood burning stoves and pellet heating systems. The company was founded in 1985 and has over 200 employees. Along with Spain, Bronpi serves all of England and other European countries. Bronpi relies completely on ABICOR BINZEL products for welding technology.

High-quality weld seams, intensive product tests

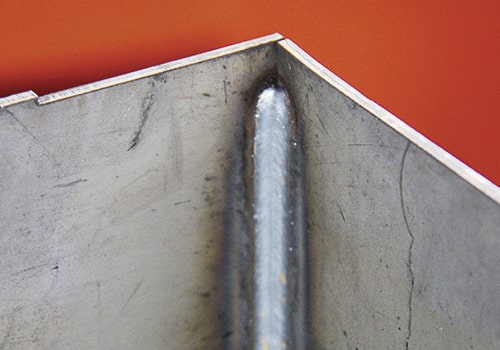

For Bronpi, welding is an important process in manufacturing. The high quality of the weld seams is a central factor for differentiating Bronpi from other manufacturers in this sector. For this reason, each weld seam and each product is tested 100% of the time.

Bronpi processes many different materials in wall thicknesses from 0.8 to 8 mm, from stainless steel to aluminium. For most products, clean visible weld seams and the absolute tightness of those seam, for example with Bronpi's boilers, are decisive. Two welding robots and numerous manual welding torches are used for joining these products together.

Sensor-guided, automated high-end welding

The introduction of the TH6D seam tracking sensor from ABICOR BINZEL was an enormous quality and productivity advance for Bronpi. TH6D is a perfect supplement for the welding robot, which is equipped with a reliable liquid-cooled ABIROB W 500 robotic MIG gun. The seam guide sensor looks for the best weld track for each weld seam and controls the robot accordingly. Since the welding robot started working with seam tracking, Bronpi needs just one hour to weld a boiler, instead of the eight hours that were previously required. In addition, the weld seams are always perfectly tight and reworking is hardly ever necessary.

Top weld seams welded manually

Bronpi still welds visible seams in wood burning stoves and pellet heaters with manual welding torches. Welders often have to work inside the stoves through small openings. ABICOR BINZEL's lightweight ABIMIG AT MIG guns with turnable, replaceable necks and different torch neck geometries are therefore perfectly suitable for Bronpi, because there is always a suitable neck available for all situations.

Read the complete article: open PDF

Is Your Robotic Welding Operation Needing to Get More Productive?

Whether it's reducing scrap, eliminating rework, or improving quality, BINZEL Robotic System solutions - from torches to periphery to sensors - gets you exceeding goals and saving costs.

Browse our complete line of robotic welding solutions by clicking the button below.

Want to talk to someone immediately? Contact us here.