Fume Extraction Systems

Fume extraction is becoming a more necessary solution for industrial companies in the wake of continued research findings and government health regulations. Having a good grasp on what fume extraction systems are and how they work is important as you begin considering fume extraction in your applications. While each system is designed for a specific purpose, fume extraction systems have one common goal - to extract harmful fumes created during the welding process.

The function of a fume extraction welding system is to vacuum out the unwanted fumes that can travel throughout your facility and harm not only your welders, but essentially all workers. These vacuum systems are designed to be powerful enough that they are extracting nearly all smoke. A fume extraction system in your plant may look like a small, portable unit that connects to a MIG gun. Another unit may be an over-head arm that sits above the welder’s station. Whatever the need is in your unique operations, there is a fume extraction system to solve the problems you are facing. Abicor Binzel believes source fume capture is the ideal fume extraction solution to optimize the health of your workplace. Our units are designed to fit with these source capture solutions along with other systems that can help get you going.

Fume Extraction System Product Solutions

There are a number of ways to look at improving fume extraction solutions in your plant. We designed products that are accessible for both manual and robotic welding operations.

ABICOR BINZEL adds three fume extraction vacuum systems to the fume extraction solutions market. Much like a conventional household vacuum, a fume extraction vacuum system is designed to house the unwanted debris, or in this case fume, from the plant. The power and durability of these machines is what allows source capture systems, like our xFUME® MIG Guns, to operate as effectively as they do. Whether you are searching for portability, user-friendliness, or high-powered systems, our fume extraction systems are the solutions you are seeking.

xFUME® Fume Extraction Systems in Action

ABICOR BINZEL has designed fume extraction systems to capture harmful weld fume at the arc to improve welder safety and overall air quality of the plant. Paired with a high-powered vacuum system, this welding fume extraction equipment provides optimal smoke extraction.

All information about Fume Extraction Systems at a glance

- How Are Fume Extraction Systems Designed?

- Fume Filtration and Collection

- How Fume Extraction Systems are Made

- Fume Extraction Portability and Flexibility

- Fume Extraction System Power

- Noise

- eBook – The Complete Guide to Fume Extraction

- Recommended Reading

- Capture Weld Fumes Where They Begin, Not Where They End

How Are Fume Extraction Systems Designed?

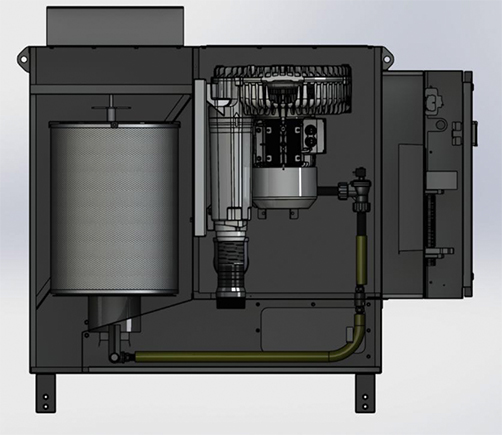

The inner housing of a fume extraction system has a filter and a motor that creates negative static pressure. From a functional standpoint it is a simple system. The unit create vacuum pressure using a motor/blower like in a shop vac. A turbine within the unit spins at a rapid rate to create the power needed to collect fumes while the welder’s welds with the torch. These industrial designed systems use specific blowers to get the very high static pressure you need to work with a welding torch.

Fume extraction systems are used for all kinds of processes that create smoke in an industrial environment. You can use a fume extraction unit with a funnel or other kind of extraction kit to sit next to a non-source capturing welding or grinding application, but many are designed specifically to deal with source capture welding, where you use an accompanying fume extraction welding gun to weld and extract fumes at the same time with the same tool.

Extraction units connect to any kind of properly fitted extraction hose kit to bring you as close as possible to the type of air pollution you are trying to capture. The most common use for a fume extraction unit is to connect to a fume extraction welding gun. But, if you weld with a TIG torch, or wish to utilize smoke extraction is a robotic application, there are funnels, boots kits, or other attachments that can be used to fit to a fume extraction system in order to collect fumes at the source.

Basic fume extraction systems are made just for one welding gun, but there are some portable systems equipped for more than one torch. These will usually feature more powerful motors and bigger filters that can handle more than one fume gun at a time. If you use an extraction system, for instance, that uses four ports, make sure your equipment requirement matches the capacity of the unit so it’s still providing the right amount of static pressure for each fume extraction gun.

Fume Filtration and Collection

The particles that are collected into a fume extraction unit can be disposed of in two different manners. One approach is having a filter that is replaceable where the particles collect on the filter membrane itself. When the filter membrane is full by being packed with dust, you simply replace the filter with a new one.

Another approach is using a cleanable filter, where you collect the particles into a membrane, clean it by pushing the particles down to a collection bin – either with a wand (pictured) or an automatic filter cleaning mechanism with the fume extraction unit, then collect the particles at the collection bin to dispose of either through landfill waste or recycling. These types of fume extraction systems with self-cleaning filters are able to be used multiple times before needing a replacement. Often, they can last up to a year in service life.

Sometimes, the vacuum unit does not provide equipment to clean the filter, so in order to clean the filter it must be removed and done manually. When the filter is needing to be cleaned, it means all of the weld fume particles have settled into the pleated material of the filter. If you don’t have a self-cleaning system withing the fume extractor unit, these filters have to be manually cleaned, which is done by removing the filter and using compressed air to separate the fume particles from the pleat. This is not considered a safe nor effective practice. The risks and hazards of doing that include releasing more metal particles into the air and contaminating the surrounding area. If a fume extraction system promotes itself as self-cleaning, but isn’t able to do so without physically removing the filter, consider your system to have disposable filters.

The other important component is the filtration of air within a fume extraction system. Some systems use a one-step filtration through a filter cartridge that you replace when full. Another have pre-filters and post-filters with HEPA – it all depends on need and the type of fumes that you will be filtering. The filter itself uses membrane filtration. You can look at the specification of your filter to make sure it filters what you are looking for. You can find filters rated for filtering chrome hexavalent particles released by welding stainless steel. The use of the right filter is critical to achieving an effective fume extraction performance and air quality.

Optional Features of Fume Extraction Systems

Among the options that exist for fume extraction systems include:

- Automatic Start-Stop

- Power Adjustment

- Automatic Cleaning

- Shunt Alarms

Automatic start-stop features activate and deactivate the fume extraction system based on whether the fume extraction gun is welding or not. Within this feature, the system will activate immediately once the welding fun begins to strike an arc. When the welder stops welding, a slight delay allows the smoke to travel through to the fume extraction system before deactivating the unit – usually between three and ten seconds. The feature is very useful in keeping the blower from unnecessary use and works to reduce maintenance costs in the unit while also reducing noise in the shop.

Power adjustment is the ability to control the static pressure of the fume extraction system. This is useful for adjusting the blower against the parameters of the weld machine. Reducing power can help for reducing noise and energy consumption. There features also help in the event of weld porosity or gas turbulence within the weld. These are not common occurrences with fume extraction welding with a higher performing fume extraction gun and extraction system.

Automatic cleaning allows for the filter to be self-cleaned by the fume extraction system when a certain level of dust collects into the filter. The system is either on a timer, or it is able to detect the need for cleaning by measuring the difference in actual static pressure against the pre-set power of the unit, which then initiates a self-cleaning of the filter. The welder can continue to weld while this process takes place.

Shunt alarms are signals – either through a light of a gauge – to signal to the welder the need to replace the filter. This feature can be part of a fume extraction system with automatic cleaning or without if you were to use a system with a replaceable filter.

How Fume Extraction Systems are Made

Fume extraction units and their outside casing are mainly made by metal sheet. They are made this way because you want a unit to hold up to use and abuse within the industrial environment of a plant. Most of these units will use plastic components on the hoods or the knows of the unit, which is fairly standard although they typically prove to be durable over time.

Inside a fume extraction unit lies the blower section, the filter section, and the dust collection section. These comprise the three main parts of the unit. The blower is the part of the unit creating the static pressure, the filter section is cleaning the air that you capture and returning filtered air back into the environment, and the collect system is where the weld fume dust accumulated through the fume extraction process.

The fumes are collected by the filter. These fumes are pulled into the filter and the particles are blocked by the membrane of the filter. Some extraction systems have a cleaning function that cleans the filter as you push the air all around the unit as dust particles drop into the collection area.

Fume Extraction Portability and Flexibility

When using overhead hoods, you are stuck with a stationary fume extraction system that serves only one purpose. The challenges of non-portable equipment are directly linked to welder safety and overall productivity issues in the welding operation.

Often times, workers may have to weld in different areas of the plant. With a stationary system, this can lead to fumes spreading and potentially never being extracted. When you move, your equipment should be able to follow. For systems that are specifically designed to solve problems, they should never cause limitations in your operation. The need for portability is a necessary component to fume extraction solutions as your workers will likely never be in one place at all times.

Investment and portability go hand in hand. As you decide which systems are best for your operation, you should consider your needs. Investing in a stationary fume extraction system may work best for a small plant or single welder, but in the long run will not be ideal as you grow and develop your facility.

Fume Extraction System Power

Fume extraction units are electrically powered either on 115 of 220 V. The difference in power requirements for these units usually comes down to the power of the motor. The more power in the motor – and the unit’s ability to collect fume – the higher the power requirement for the system. It’s important to know what your specific welding application requirements are when looking at a fume extraction system. Factors like metal type, wire size, amperage rating, weld position, and wire feed speed will all have an impact on the static pressure and flow requirement you will have for the right fume extraction system.

Fume extraction systems come in two styles from a power perspective: high vacuum and low vacuum systems. A low vacuum system will use less power and produce less flow, which may not be suited for all styles of fume extraction MIG guns. These entry-level units typically will have small filters and limited features. Within the family of high vacuum portable extraction systems there are many options and features. The main features are the capacity and strength of the blower to make sure it fits the application. The less powerful unites are in the 1-kilowatt range, while the most powerful fume extraction systems – at least for a portable system – can get up to 8-kilowatt in power.

The vital part of any fume extraction system is the blower. The flow and pressure the blower creates will be proportional to the electrical requirements.

Noise

Portable fume extraction systems typically generate a lot of noise. The size of the motor and power of the blower will create a definite noise intensity.

The better units will use a system that dampens the level of noise created. Usually 68 to 85 dba is a commonly accepted decibel level for a portable fume extraction unit.

Recommended Reading

- Fume Extraction System Problems and Solutions

- How to Test Your Fume Extraction System

- 5 Fume Extraction Questions You Should Know Before Starting

- Fume Extraction Units: Tell a Good One from the Rest

- Fume Extraction Filter Review: Picking the Best Filter for the Job

- 3 Problems with Contact Tips (and How to Overcome Them)

- Understanding Contact Tips

Capture Weld Fumes Where They Begin, Not Where They End

Get started and talk with an ABICOR BINZEL Fume Solutions expert.