Stahl Maschinenbau GmbH & Co. KG, Perkam, Germany

Reliable series production of hydraulic tanks

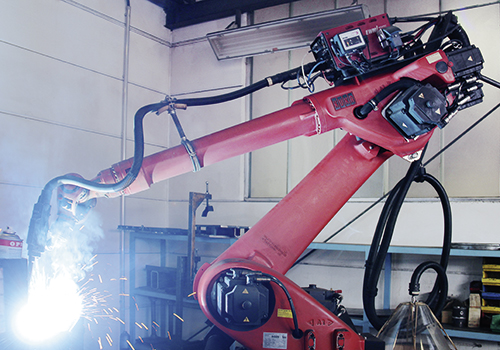

Stahl Maschinenbau in Perkam, Bavaria, specialises in the development and production of hydraulic and diesel tanks for construction machines, cranes and industrial lifts. The company meets the high standards for quality and series production among other things through the use of robot welding technology from ABICOR BINZEL.

Precision comes first

Stahl's customers include Caterpillar, Sennebogen, which manufactures cranes for transhipping and the plant manufacturer Eisenmann. Finished hydraulic and diesel tanks must be 100% leak-proof, and this is why welding them demands great precision and the exact consideration of material distortion through the temperature load.

Stahl relies on automated welding with welding robots for the series production of tanks holding 200 to 2000 litres. The company also has 25 manual welding stations available for tanks that have to be adapted individually. In both cases, MIG/MAG welding torches from ABICOR BINZEL are used.

Flexibility and economic efficiency

The manual welding stations are equipped with reliable and robust MB GRIP 401 D and 501 D welding torches. The welding robots have WH W 500 welding torches with a special torch neck design. These are characterised by quick and flexible adaptation of the torch necks to changing welding tasks. This means that Stahl is able to manufacture many different tank models with two welding robots.

Stahl successfully made a huge step in the direction of greater economic efficiency with the use of the ABICOR BINZEL's EWR (Electronic Welding Regulator) gas saving unit. Gas consumption subsequently fell by 50%, so that operating costs were reduced accordingly. In addition, the EWR improves gas shielding as well, which again increases process reliability and weld quality.

Read the complete article: open PDF