Spool Welding Robot SWR

The collaborative welding robot to maximize performance in pipe production

With this Spool Welding Robot SWR you can increase the efficiency of your pipe production and reduce costs for pipe processing at the same time. Efficient welding technology and statistical reporting create synergies that guarantee consistently high quality. This collaborative welding robot maximizes production and flexibility in pipe production and reduces operating costs at the same time. Novarc Technologies and ABICOR BINZEL present the innovative Spool Welding Robot SWR – for welding pipes as turnkey solution.

Advantages at a glance:

- Continuous welding pipes from root to cap

- Always clear view of process with NovEye® camera

- Documentation of welding parameters with NovData® data collection system

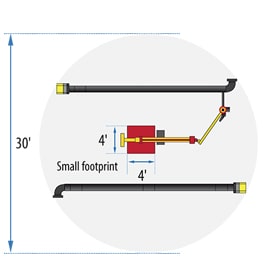

- Its open platform with a small footprint of 1,2 m x 1,2 m allows up to 5 positioners by using small space of pipe production process

- Ideal for welding pipe spools by GMAW & MCAW

- FCAW as optional package

- Offered as production solution

Spool Welding Robot Overview:

High-class technology by ABICOR BINZEL

With this Spool Welding Robot SWR you will get an excellent combination of ABICOR BINZEL welding solutions to achieve consistent quality and best results in pipe welding. These are in detail:

- ABIROB® W robot welding torch

- TH6D seam tracking sensor

- MasterLiner

- EWR 2 / EWR 2 Net as optional equipment

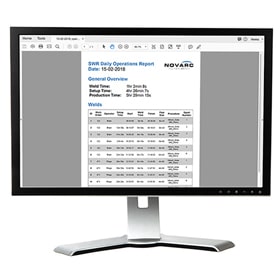

Process monitoring and analysis

With the innovative NovEye® camera and the NovData® software, machine operators and welders have a very clear view of the welding process and the welding parameters during pipe production:

- Weld performance (i. e. current, heat input, travel speed, wire feed speed, etc.)

- The weld during operation

- A daily operations report

Small footprint

Simply install your pipe welding cobot for pipe production in your production hall. With its very small footprint, it takes up an area of just 1.2 x 1.2 m – with a maximum reach of 4.5 meters:

- Use up to 5 positioners

-

Existing positioners can be integrated into the SWR

Easy to operate

With this collaborative robot, pipes can be welded faster and more effectively from root to cap:

- Simple operation that is just as easy to carry out by young welders as it is by plant managers or experienced welders

- No specific programming knowledge required

- No housing necessary

Just plug, set, weld.

Spool Welding Robot Videos:

SWR – the cobot for pipe welding

Explainer: Spool Welding Robot SWR

What is the Spool Welding Robot?

SWR Welding Various Pipe Shapes, Sizes, & Types

ABIROB® W and Spool Welding Robot

Spool Welding Robot vs. Manual Pipe Welding

TH6D Laser Seam Tracking and Spool Welding Robot

FAQs:

Whether or not to use a collaborative Spool Welding Robot in pipe production surely brings up many questions. To make things easier for you and get answers right away, we have collected the 22 most frequently asked questions on the collaborative Spool Welding Robot. We hope, these will help you in the first instance.

Safety

The Spool Welding Robot meets all the safety requirements of ISO15066; therefore, the installation of a housing or safety curtains is not required.

Ratio of reach

Compared to industrial spool welding robots, the SWR has the largest ratio of reach to footprint. E. g. your shop’s footprint is limited to 2,23 m². In that case, the SWR still has a range of 4.5 m (radial) for a maximum pipe diameter of approx.1.5 m (depending on the positioner configuration).

Ergonomics

The SWR improves the ergonomics of pipe welders. It brings the welder out of rigid position while welding and takes over the weave motion. It strains off the welder‘s back and shoulder joints.

Data logging and reporting

NovData logging software allows analysis and reporting of your weld data. All welding data are stored and available for you. These data are for example heat input, positioner speed, wire feed speed, etc.

Monitoring

Each weld is stored by the NovEye monitoring system. That allows your employees to analyze and improve their process for the next welds.

Seam tracking & distance control

The SWR assists the operator in torch to pipe distance by using a laser camera and closed loop control system. With this, the operator is automatically assisted in seam tracking and can primarily keep his focus on the weld.

Collaborative robots – cobots – are industrial installations which can safely collaborate with operators in a production line. They do not require knowledge about robot programming or special programming language. They are very easy to operate and can partly be moved by hand.

Universal Robots, Fanuc, Yaskawa and others are manufacturers for six-axis Cobots on the market today.

With the base model of the SWR you can weld pipes of standard wall thickness, meaning Schedule 40 and Schedule 80 pipes. In case you need to weld pipes in your pipe processing outside these spectra, tell us about your application and we are happy to help you.

The main welding processes are: gas metal arc welding, flux-cored arc welding and metal-cored arc welding. On root we use modified short-circuit (STT, RMD, LSC). For modified waveform pulse processes we use solid wire and flux core or metal-cored wire for fill and cap passes.

With the Spool Welding Robot you can weld mild steel, stainless steel and special alloys in pipe processing.

Yes, you can. You will get quality welds with almost any standard pipe positioner to work with the SWR in your pipe production.

Taking the industry standards into consideration, the SWR falls under mechanized welding – when the operator interacts with the machine.

The Spool Welding Robot has a 1.2 x 1.2 m footprint. With this small space the SWR does not block traffic in the shop floor and it does not interfere with shop cranes. Its arm and boom can be extended and retracted to accommodate activity on the pipe production floor.

The SWR pipe welding robot increases productivity in pipe production thanks to its flexible functionality. It can integrate up to five positioners and thus enables »overlapping« cycle times and parallel work. That means: while the collaborative robot is welding on a pipe, finished components are taken off and the positioner is equipped again. The change between position or workstation is also partially automated. In this way, work cycles in the interpass temperatures can be maintained. This results in an almost 100 percent arc-on time during a shift in pipe processing and thus a significant reduction in incidental costs. As a result, productivity can be increased up to three times, which in turn increases the capacity of a pipe production many times over.

Torch hand control goes over to the SWR and with that relieves welder’s fatigue. The Spool Welding Robot has a higher deposition rate, higher production and faster track speeds. Above that, it has the ability to run pre-programmed welds.

Yes, it is easily possible. The Spool Welding Robot SWR fits in pipe fabrication shops very easily because its height does not interfere with overhead cranes. And if you want shop traffic to pass, just park the SWR away.

Installation takes two days and only one more to commission according our conditions.

An operator can be trained within 2-3 days, then he/she can do operations and maintenance.

The operator should already have some basic welding experience.

When you order the SWR, you will also get the NovData™ production monitoring software along with it. That software produces daily reports, which includes the following information:

- Production time

- Welding time

- Pipe diameter

You also get a time-stamped log file with:

- Voltage

- Weld current

- Wire feed speed

- Travel speed

- As well as other relevant weld parameters and motion parameters for each weld

The Spool Welding Robot also has a built-in camera, mounted into its robotic arm. This allows the operator to get a clear view from inside the groove on the HMI in real time. And to have data for future analysis, NovEyeä records all videos.

The shielding gas used depends on the weld process and filler metal.

The Surface Tension Transfer (STT) is highly tolerant of pipe prep variations. The Spool Welding Robot requires no more than 3mm hi-lo in pipes, even less.

The SWR needs 3 phase power and a minimum of 5,5 bar compressed air. The required electrical power can be any of the standard voltages between 208V and 600V.

The Spool Welding Robot has built-in systems to monitor speed and torque. These ensure speed and forces within required levels at all times.

The Spool Welding Robot is a robust machine. Therefore, only minimal maintenance is required. When you get operator training, maintenance training is also included.

The Spool Welding Robot needs to be anchored to a minimum 15 cm concrete slab. With overhead cranes you can move it between previously installed base locations.

The SWR can be used outside the pipe shop as long as it is protected from the elements. Basically, it is designed for indoor usage.

The weight of the Spool Welding Robot is approximately 1400 kg.