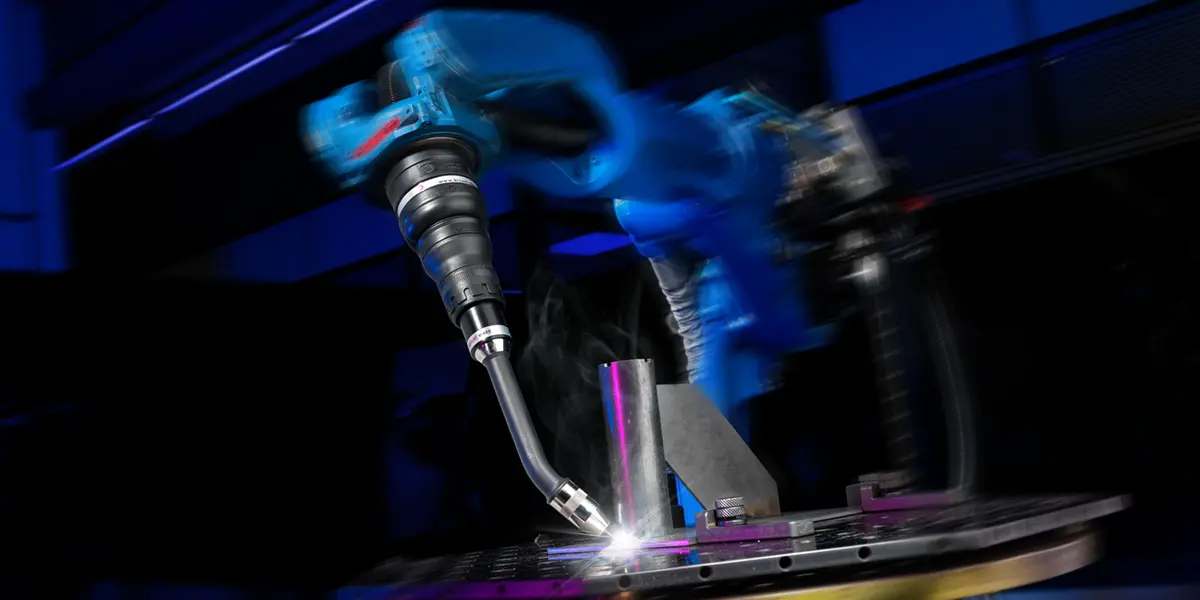

MIG/MAG Welding Torch System ABIROB® W

Robust & flexible ...

Pure ROBO power! Liquid-cooled ABIROB® W welding torches have power ratings up to 600 A and are equipped with state-of-the-art cable assembly and interface technology. The modular design of these rugged yet flexible torches allows a fast change of torch neck and cable assembly components without the TCP (Tool Centre Point) changing – thus avoiding additional programming effort.

High repetitive accuracy and a continuously precise welding process are ensured through the innovative but “simple” torch construction.

All information at a glance

Advantages that speak for themselves:

- Robust torch necks with screw-on gas nozzle and replaceable contact tip holder guarantee high durability and a long service life cycle

- The innovative interface design ensures the fast change of torch neck and reproducible positioning of cable assembly and torch neck

- Hybrid cable assembly technology for optimized wire feeding, prevention of electrolytic corrosion and improved coolant flow

- Special torch neck geometries are available for joining components even with limited accessibility

Application areas:

- Commercial vehicle construction

- Earth-moving equipment

- Rail vehicle construction

- Shipbuilding

- Container construction

- Machine and steel construction

- Aerospace industry

Material:

- Construction steels (coated / non-coated)

- Chrome-nickel steels

- Duplex steels

- Nickel basic materials

- Mixed compounds

- Aluminium materials

- Magnesium materials

- Copper materials

- Special materials

Robot interface:

- Conventional robot (Cable assembly external):

− Robot mount CAT3 PRO

− Fixed bracket RTM - Hollow wrist robot (Cable assembly internal):

− Robot mount iCATmini

− Bracket iSTM (for robots with integrated collision software) - Hollow wrist robot (Cable assembly external):

− Robot mount CAT3 PRO

− Fixed bracket RTM

Technical data according to EN 60974-7:

| Type: | ABIROB® W 50 | ABIROB® W 300 | ABIROB® W 400 | ABIROB® W 500 | ABIROB® W 600 |

| Cooling: | liquid cooled | liquid cooled | liquid cooled | liquid cooled | liquid cooled |

| Rating: | |||||

| CO2: | 550 A | 330 A | 470 A | 550 A | 600 A |

| Mixed gases M21*: | 500 A | 300 A | 400 A | 500 A | 550 A |

| Duty cycle (%): | 100 | 100 | 100 | 100 | 100 |

| Wire-Ø (mm): | 0.8 - 1.6 | 0.8 - 1.2 | 0.8 - 1.6 | 1.0 - 1.6 | 1.0 - 1.6 |

| Torch angle: | 0°/ 22° / 35°/ 45° | 45° | 0°/ 22° / 35°/ 45° | 0°/ 22° / 35°/ 45° | 0°/ 22° / 35°/ 45° |

* Mixed gases M21 (according to DIN EN ISO 14175)