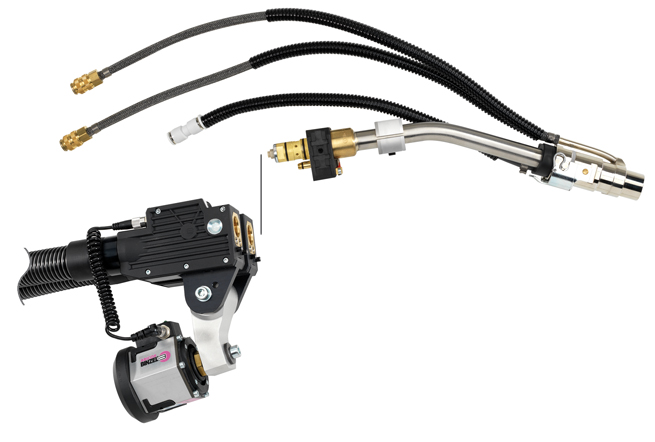

MIG/MAG Welding Torch System TANDEM

Top-level power ...

Tandem welding makes high demands on the whole equipment. The WH W800 is a reliable and technically matured torch for welding in the high-power range.

Based on the tried-and-trusted WH system, almost all welding applications in this range can be carried out using the WH W800 – thanks to the different torch geometries. Three individual cooling circuits guarantee optimum temperature behaviour.

Advantages that speak for themselves:

- Simple and quick maintenance

- Use of standard WH cable assemblies

- Quick-action connection for gas nozzle, different contact tip lengths available

- Optimally matched to the power source technology of various manufacturers

- Compact and powerful with two separate potentials

- Three individual cooling circuits (gas nozzle and both cable assemblies)

Typical areas of application:

- Suppliers (Tier 1, Tier 2)

- Commercial vehicle construction

- Earth-moving equipment

- Rail vehicles

- Container construction

- Machine and steel construction

- Aerospace industry

Material:

- Construction steels (coated / non-coated)

- Chrome-nickel steels

- Duplex steels

- Nickel basic materials

- Mixed compounds

- Aluminium materials

- Magnesium materials

- Copper materials

- Special materials

Robot interface:

- Conventional robot (Cable assembly on the outside):

−Robot mount CAT3 PRO

−Fixed bracket RTM

Definition of the degree of automation:

Low = Torch neck change not possible

Medium = Torch neck change possible (manually)

High = Torch neck change possible (manually & automatically)

WH TANDEM W800 (liquid cooled)

Technical data according to EN 60 974-7:

| Cooling: | liquid cooled |

| Rating: |

2 x 450 A CO2 2 x 400 A Mixed gases M 21 (EN ISO 14175) |

| Duty cycle: | 100 % |

| Wire-Ø: | max. 1.6 mm |