Products by Product Group

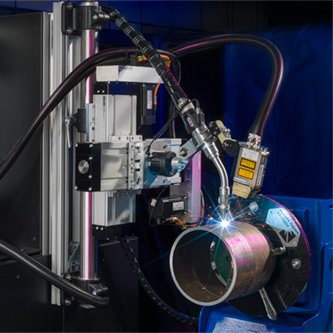

Find MIG welding solutions to start reducing costs and improving uptime or browse through our industry-best Manual, Robotic, or Laser welding options.

Join BINZEL USA in exploring our webinars

View our sessions to sharpen your skills and knowledge.